All About Tyres

Tyre Care

A blown tyre can cause all sorts of damage to a caravan/camper. The worst-case scenario is if it completely lets go and explodes, as this can do damage to the structure of the caravan.

The most common car today for towing is the dual cab ute. The common dual cab utes on the market weigh roughly 2,400-3,000kg when loaded up. That’s roughly 600-750kg on each tyre, which isn’t too bad.

Now here’s the scary part – the average caravan can range from 2,200-3,000kg on a single axle. That’s 1,100-1,500kg on each tyre, yikes! So straight out of the driveway your caravan tyres are under double the stress of a car tyre.

It’s absolutely key to be sure you have the correct tyre before you set off. This means having the correct construction and load rating of the tyre. But we’ll get to that later.

Let’s say that you already had the greatest tyre you can buy on your van, but the caravan has been stored for a few months and you’re planning a fairly decent trip away. Here are some tips for maintenance and care before venturing off into the great blue yonder!

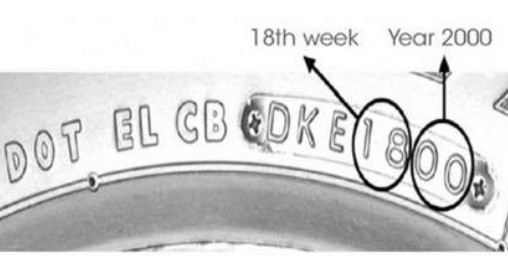

A couple of weeks prior to your departure date, I recommend doing a simple check, which is just a brief look at the tyres. Take a look at the sidewall for any surface cracks, colour fading or signs of fatigue. These signs will be significantly more noticeable if the caravan is stored uncovered, as the tyres will be going through heat cycles with the changing of day and night temperatures, as well as lots of UV rays. Also there is a 4 digit number on the tyre which will indicate when the tyre was made- See Tyre Age

Another obvious point to make is if the tyre is flat or doughy there may be a slow leak somewhere, and you’re best to have it looked at by a tyre shop. Slow leaks can be anything from a leaky valve, small hole, or worse, a damaged or cracked rim, which can happen with aftermarket rims that don’t have correct load rating. It can also happen if they’ve copped some abuse on the last trip you took.

If you need to change a tyre it’s definitely a good idea to have the tyres on the same axle at roughly the same tread wear depth. For instance, if you get a flat tyre that needs replacing, and the other tyre is only half worn, it’s best to replace them both. This is because having different tread depths can create imbalance, particularly in emergency situations.

If the tyre looks good, that’s great. The next top tip would be to go for a drive, say half an hour or so. This will do many good things. Firstly, it warms the tyres up and gets them moving, which will expose any new surface cracks on the sidewalls. Secondly when a caravan is parked for long periods of time the footprint of the tyre tends to form a flat spot, and by driving around moving the tyre and warming it up, this tends to release that flat spot. If it doesn’t then you might be best to get it checked out.

If your tyres all check out ok, the last thing I would recommend before a trip is to have the tyres rotated, and have a wheel alignment done to the caravan.

Tyre Age

Tyre Pressures

Tyre pressures are the most talked about and possibly the least understood of all matters relating to tyres. After a lifetime of rallying, advanced driver training and travelling in the remotest parts of Australia, including 22 Simpson Desert crossings, 21 Cape York trips and 9 Canning Stock Route trips as well as many more. I can tell you that I’ve learned a great deal about tyres. One of the things I have learned is that everyone is an expert and most people have no clue.

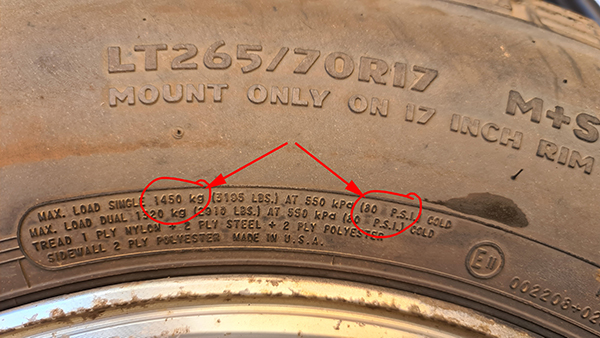

You car and caravan manufacturer recommend specific tyre pressures. These are usually written on some kind of label, in the case of the car, on the B pillar. These pressures are a guide. They may be correct in most circumstances, until you significantly change load or change tyre type and size. In my opinion, the best information is the information supplied by the tyre manufacturer which is written directly on the tyre. However, it requires some interpretation.

Let me do a quick couple of examples

We’ll use the tyre information above and the information from our car manufacturer

Let’s say our car is a Land Cruiser 200, Toyota has specified a front axle load of 1630kg and a rear axle load of 1950kg, giving a total of 3580kg. This is 230kg over the Land Cruiser’s GVM of 3350kg, so it allows a little uneven loading of the axles without exceeding the GVM. We’ll say that our LC200 is loaded evenly just for this example and we’ll say that the load is just under GVM, at 3000kg to make the math easier.

This means that in our example, we’ve 1500 kg on each axle or 750 kg per wheel/tyre.

Taking the information form the tyre we can see the following

Max Load allowed = 1450 kg

Max Pressure allowed = 80 psi

We calculated the correct pressure for ANY load using this formulae

Pressure = Actual load on the tyre/Max tyre load allowed x Max Pressure + 4 psi

So we get Pressure = 750/1450 x 80 psi + 4psi

=> Pressure = 41 +4 = 45 psi

This calculation works for all tyres and loads. I have seen many who recommend something similar to the above but don’t add the 4 psi, so as to make the calculation simpler, but this puts you at the bottom of the proper range and in a few weeks your tyres will be too flat. They also run a little hotter at the lower pressure.

So now I hear the quicker thinkers say but what if I have a higher load and when I add the 4 psi, I go over the maximum pressure allowed? e.g.

Max Load allowed = 1450 kg

Max Pressure allowed = 80 psi

Our load = 1440 kg

Pressure = Actual load on the tyre/Max tyre load allowed x Max Pressure + 4 psi

So we get Pressure = 1440/1450 x 80 psi + 4psi

=> Pressure = 79 + 4 psi = 83 psi

Easy! We must never exceed the maximum pressure or the maximum load. So in this case we would put 80 psi in the tyres. In the long term, we would be better off finding a tyre that has a load rating that places us closer to the middle of the range as this tyre’s life will be somewhat shortened.

What about Off-Road Pressures for my off-road camper? Please see the Off-Road Course.

Extra Information

Tyre Types and Specifications

There are so many tyre types that we would not be able to cover them in detail here but we’ll talk about a few.

Radial v Bias Ply

Bias Ply Tyres

With a bias-ply tire, the individual cords that make up each ply or layer within the carcass of the tire run at an angle across the body of the tire from one bead to another. Though the angle varies, for the purposes of illustration let’s say they run at a 45-degree angle relative to the face of the tire. Additional plies within the tire run at opposing angles, or in bias, hence the term bias ply. The cords that make up the plies in a bias-ply tire are often made of nylon, rayon, polyester, or some other non-metallic material. There are typically multiple plies (layers) within the carcass of a bias ply tire, but the number of plies in the tread face is usually the same as the number of plies in the sidewall. The number of plies will have an impact on the load-carrying capacity of the tire as well as its resistance to impact breaks.

Radial Tyres

A radial tire has cords that run straight across to each bead, perpendicular to the tread face, rather than running at an angle. Further, there are additional plies that run at an angle within the tread face of the tire only, so a radial tire might only have two layers within the sidewall but five or more in the tread face. Radial tires also usually have steel cords. A radial’s construction means it’s usually tough on the tread face but more vulnerable to impact breaks in the sidewall.

Before we examine the advantages and disadvantages, it is fair to say that you would find it difficult to purchase a bias ply tyre suitable for most trailer s and caravans. The below therefore is a rather philosophical/technical discussion that explores perhaps why serious off-roaders e.g. (rock climbers) use bias ply tyres.

Load-Carrying Capacity

Advantage: Bias Ply

Due to their multiple layers, bias ply tires generally have the advantage when it comes to load-carrying capacity. Because there are a uniform number of plies to support the weight of a vehicle in both the tread face and the sidewall, bias ply tires are generally better when hauling heavy loads. This is why trailer tires, tractor tires, and heavy equipment tires are often bias ply; they can better support heavy loads. Radials are available with high load ratings, but the weight-carrying capacity requires adding many more plies to a radial tire, making them very stiff.

Speed / Heat Dissipation

Advantage: Radial

Any tire manufacturer will tell you that the number one killer of a tire is heat. Heat is caused by several factors, including tire pressure, weight, and speed. As a tire rotates, the sidewall and tread face move, and this movement causes heat. The faster the speeds or the higher the weights, the faster a tire will heat up. A radial tire is better about dissipating heat than a bias ply tire for several reasons. It’s also worth noting that the higher the speed rating of the tire, the lower the weight rating. This is also why it’s a good idea to reduce speeds when towing with bias ply tires; a bias ply tire may last for years at 55 mph but fail at speeds of 80 mph simply because it can’t dissipate the additional heat created by the additional speed. Slow-speed, heavy applications like a full-size rockcrawler might actually do better with a bias ply tire than a high-speed radial intended for a trophy truck.

Puncture Resistance

Advantage: Bias Ply

This one might be controversial because the number of plies in a radial can vary quite a bit. Generally speaking, though, a radial tire has vulnerable sidewalls due to the reduced number of plies compared to an equivalent bias ply. Though there are several radials marketed to off-roaders with reinforced sidewalls opinion varies on whether or not most of them are truly as strong as a bias ply tire. Indeed, few people will argue that bias ply tires are capable of handling a lot of off-road abuse, while the strength of radial tires off the pavement varies quite a bit according to the manufacturer and the individual tire model. Sidewall failures are much more common on radials in an off-road environment, Puncture resistance is one of the biggest reasons that bias ply tires are the standard in agricultural, industrial, and slow-speed off-road applications.

Torque Splitting

Advantage: Bias Ply

Related to puncture resistance, torque splitting (sometimes called “zippering”) should be a strong consideration for off-roaders. Though the term is not well known known, it refers to an injury further splitting or expanding under load. For example, let’s say there’s a puncture in the sidewall of a tire. Due to the multiple layers and construction of a bias-ply tire, that break in the sidewall will most likely be confined to the spot where the actual injury took place. With the construction of a radial tire, there’s a strong possibility that the site of the puncture will expand rapidly as torque and load is applied, resulting in a much larger tear or rip than the original puncture site. Why is this important? A puncture with a bias ply tire will most likely stay small, so it can be temporarily repaired with plugs out in the woods until a proper repair can be made. With a radial, there’s a much stronger chance that the site of the injury will result in a tear that will be well beyond what temporary plugs can handle, so you’re stuck without a spare tire. These tears can happen in the tread face as well, rendering a radial tire unrepairable when a bias ply could be repaired and returned to service.

Pavement Manners

Advantage: Radial

There’s no reason to sugar-coat it: radial tires outshine bias ply tires in everyday on-pavement ride and handling situations. Indeed, this is one of the big reasons that radial tires have become the standard in cars and light trucks since the early 1980s. A bias ply tire tends to follow ruts, cracks, and road irregularities, while a radial tire tends to skip over those same irregularities without transmitting them to the vehicle. Bias ply tires also flat-spot, meaning if the vehicle sits for a period of time, usually just overnight, flat spots develop in the section of tread in each tire was on the ground. The flat spots go away as the tire rolls and warms up, but this can make for a very uncomfortable driving experience for the first 15 minutes or so, especially if the vehicle has been sitting for several days. It should be noted that radials do flat-spot, especially when the vehicle sits for several days. Radials tend to flat spot less than a bias ply. For these reasons alone, radials are a better choice for daily drivers that see primarily street duty.

Performance Handling

Advantage: Radial

Not all loads on a tire are straight down. In performance applications, tires see significant side loads as a vehicle moves through corners. The attributes that give a radial good overall pavement manners are the same ones that make them superior when it comes to handling abrupt corners, sweeping turns, and other performance maneuvers. A bias ply tire doesn’t respond as well to cornering forces, especially as the width of the sidewall increases. In straight-line handling there is little difference between a radial and a bias ply, but cornering performance varies significantly. Fortunately trucks shod with big tires aren’t expected to whip around corners like a sports car, so this is less of a concern in most off-road applications. But it’s worth noting that bias ply tires can make a vehicle feel lazy and less sure-footed during abrupt cornering maneuvers.

Traction

Advantage: Tie

Because there are fewer plies, especially in the sidewall, a radial tire is more forgiving and better about conforming to terrain irregularities, especially when tire pressure is lowered from the recommended specifications printed on the sidewall. Because of its additional sidewall layers, a bias ply tire tends to be stiff and less confirming. However, real-world off-road experience shows that simply lowering the air pressure of a bias ply tire a few more pounds than an equivalent radial will cause it to act much the same as a radial. And, because lowering tire pressure for additional off-road traction exposes the sidewall to more potentially damaging objects, a bias ply tire tends to be stronger and less likely to suffer a puncture. Most off-roaders will gladly exchange some extra stiffness for better cut resistance, since a flat tire isn’t much good to anybody. Bias ply tire construction also makes them better suited to more aggressive treads with wider voids between tread blocks, and these tread patterns can clean themselves out more easily than more tightly packed tread patterns with lugs closer together.

Tire Selection

Advantage: Radial

Because radial tires are so widespread, there is a much greater selection of radial tire sizes and styles available. Street tires, all-terrains, mud-terrains, and more are available in an enormous variety of sizes. With few exceptions, consumers usually don’t have many problems finding a tire for their needs in whatever reasonable tire size they desire. Bias ply tires for light trucks have become more of an enthusiast tire, with more limited tire sizes and styles available. The styles also tend to be on the more aggressive end of the spectrum, such as the Irok or the classic Super Swamper TSL. The selection evens out quite a bit with trailer tires (again, due to bias ply load-carrying capacity advantages), but most popular sizes are available in both bias and radial options.

Big Tire Sizes

Advantage: Bias Ply

While tire selection may be limited, bias ply tires still rule the roost when it comes to really big sizes. It is difficult to manufacture a radial in very large sizes, so as a result, most tires above about 42 inches in diameter are going to be bias ply. If really big tires are part of your build plans, more than likely you are going to end up rolling on bias-ply tires.

Conclusions

In today’s world it often seems as though radial tires are the clear-cut choice for any truck owner. While it’s true that a radial is generally a better choice for a vehicle that spends most of its time on the pavement, there are still some strong advantages to a bias ply tire when it comes to a vehicle that spends quite a bit of time off the pavement. In many ways, bias ply tires are arguably a better choice for pure off-road use, especially when you’re after the big, burly aggressive look. While there is no right or wrong answer to the radial vs. bias ply question, hopefully now there’s a better understanding of where each type of tire performs better so that consumers can make more educated buying decisions.

Light Truck Tyres and Trailers

What are light truck (LT) tyres?

Light truck tyres are made for light duty and heavy duty trucks and vans.

Designed for traction and strength on and off the road with a load capacity ranging between ½ ton and 1 ton.

They’re built with a robust internal construction and the ability to withstand on-road obstacles such as bumps and potholes. This is great, particularly for working vehicles that frequently travel in industrial areas where roads aren’t as smooth.

Light truck tyres feature a meatier tread pattern than highway terrain tyres and strong sidewalls that provide enhanced protection from exterior damage. They are also capable of carrying heavy loads which makes them great for industrial work and towing.

What does LT on a tyre mean?

You can quickly and easily check to see whether your vehicle is fitted with Light truck tyres by looking at the tyre itself. Simply, look for ‘LT’ marked on the outside of the wheel.

Do I need light truck tyres?

When considering light truck tyres for your truck or ute it’s best to think about how you plan to use your vehicle each day.

Is it regularly going to be carrying heavy loads?

Do you need tyres equipped for towing increased weight such as that of a caravan?

Are you looking for a more robust and resilient tyre with the ability to handle uneven on-road surfaces and some off-road terrain?

If you answered yes to the above, light truck tyres may be a great option for you.

What are commercial tyres?

Commercial tyres are made to endure the challenges of working vehicles. With performance and durability in front of mind they are tough tyres that are suited best to trucks, buses, mining vehicles, tractors and agricultural vehicles.